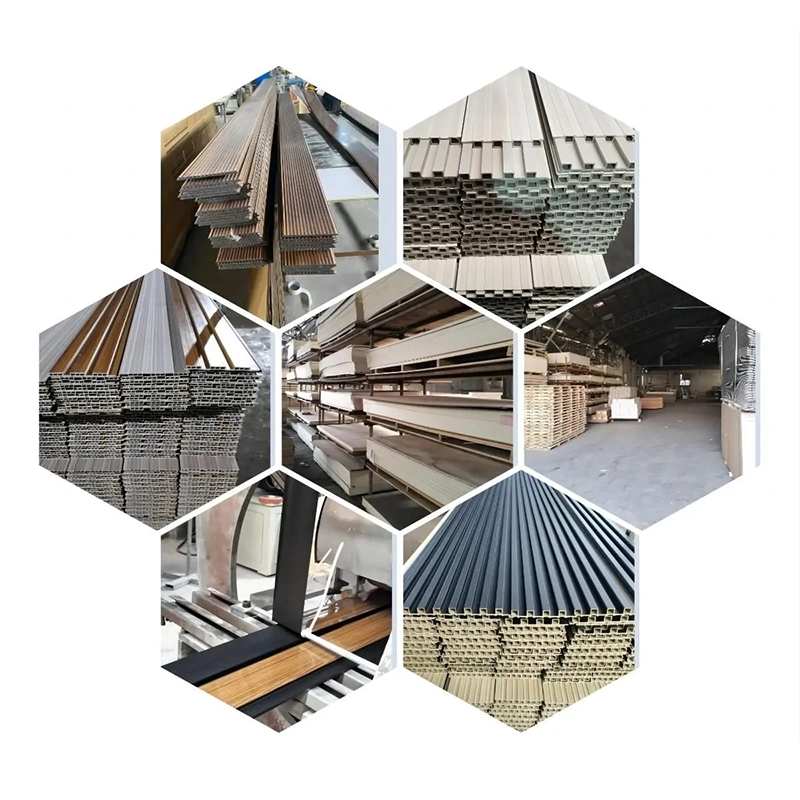

Leading Local Plywood Manufacturer in Kegalle Sri Lanka.

Widely used for construction materials and Day to day Works.

| Items | Details | Items | Details |

|---|---|---|---|

| Size | 1220x2440mm,1250x2500mm,1250x3000mm,or as Customized | Thickness | 2.7~30mm |

| Face/Back | Birch,Pine,Okoume,Poplar,Melamine,According to your needs | Core Material | Birch,Eucalyptus,Poplar,Combi core or as request |

| Grade | Commercial Grade,Furniture Grade,Premium Grade | Glue | Phenolic,WBP |

| MOQ | 1*40HQ | Moisture Content | 8%~16% |

| Density | 650-860kg/m3 | Usage | Furniture,Laser Die Cutting,Toy,Loud Speaker,Construction,Flooring,etc |

| Certification | FSC,CE,EUTR,CARB,EPA | ||

Commercial plywood Factory - zzplywood® - China Formwork Plywood Manufacturer

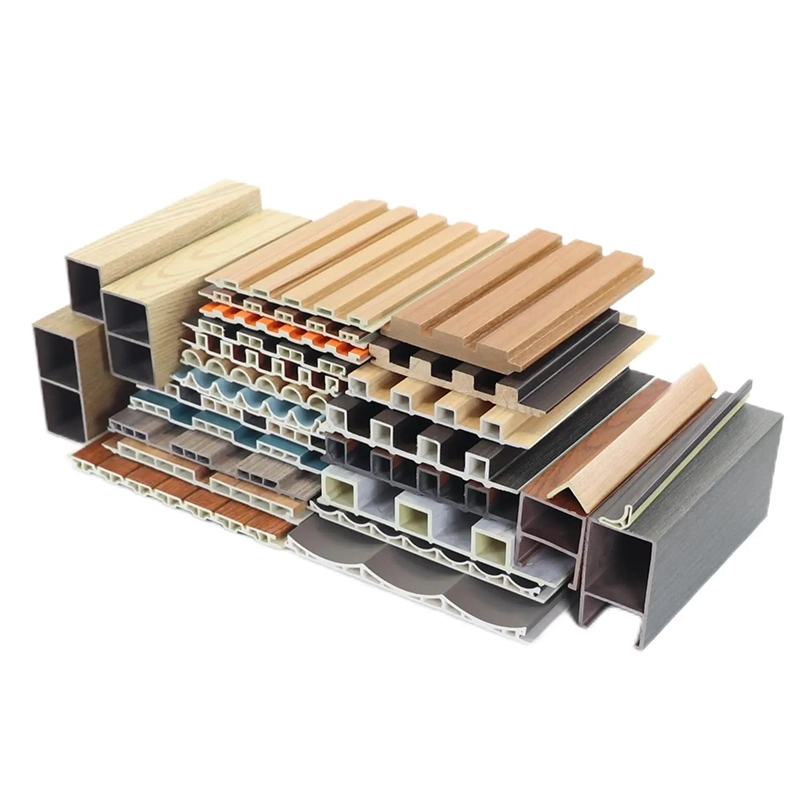

It is meticulously crafted by laminating multiple layers of high – quality wood veneers. These veneers are sourced from sustainable forests, ensuring not only top – notch quality but also environmental responsibility. The cross – grain orientation of the layers enhances the plywood’s structural integrity, distributing stress evenly and making it incredibly strong.

Core material

Whether it’s for constructing the framework of a large – scale commercial building or supporting the weight of industrial equipment, our commercial plywood can handle substantial loads. Its robust composition makes it a reliable choice for structural applications, giving you peace of mind that your project will stand firm for years to come.

Finger Joint Blockboard

Glue: WBP Melamine

Thickness: 12/15/18mm

Reuse: 2-4 timesPrice: Cheap

Finger joint core is composed of smaller pieces of wood joined together with finger-like interlocking joints.

It offers excellent strength, stability, and resistance to warping or splitting.

Finger joint core is often used in high-quality plywood for applications that require superior structural integrity, such as construction, flooring, and furniture manufacturing.

Poplar

Glue: WBP Melamine

Thickness: 8/10/12/15/18mm

Reuse: 6-10 times

Price: Medium

Poplar core is made from the lightweight and straight-grained poplar wood.

It is known for its stability, ease of use, and affordability.

Poplar core plywood is commonly used in interior applications like cabinetry, paneling, and decorative projects where weight and cost are important factors.

Poplar

Glue: WBP Melamine/Phenolic

Thickness: 12/15/18mm

Reuse: 10 - 15 times

Price: Premium

Eucalyptus core is derived from the fast - growing eucalyptus tree, known for its strength and durability.

It provides excellent stability, resistance to moisture, and high load - bearing capacity.

Eucalyptus core plywood is often used in outdoor and marine applications, including boat building, exterior construction, and infrastructure projects.

Glue Types

WBP Melamine (Water Boiled Proof Melamine) is a synthetic resin adhesive. It is known for its excellent water resistance and durability, making it suitable for exterior and marine applications. WBP Melamine glue creates a strong bond that can withstand exposure to moisture, humidity, and changes in temperature. It is commonly used in construction, concrete formwork, flooring, and other applications where plywood needs to withstand harsh environmental conditions.

When it comes to plywood glue, two common types used for their superior bonding properties are WBP Melamine and WBP Phenolic.

Film Types

Anti-slip film

The special anti-slip film is usually used in the workshop to prevent the traffic of vehicles.

zzplywood® Plywood Veneer Film >>

Black Film

Black Film is a popular choice for film-faced plywood due to its high contrast and aesthetic appeal. It provides a smooth and uniform black surface that offers good resistance against water, chemicals, and wear.

Brown Film

Brown Film is widely used in the construction industry for its durability and cost-effectiveness. It offers good water resistance, strength, and protection against external elements. Brown Film-faced plywood is suitable for various applications.

Red Film

Red Film is known for its vibrant red color, which provides an eye-catching appearance to plywood. It offers similar properties to other film types in terms of water resistance, strength, and protection.

Edge Seal - Waterproof

Waterproof edge sealing is an essential step in plywood protection and longevity. It helps prevent moisture penetration and protects the edges from damage. Remember, proper edge sealing is crucial to maximize the performance and longevity of form plywood, particularly in applications where exposure to moisture is expected. By taking the necessary precautions and using high-quality sealants, you can ensure the long-term durability and water resistance of your plywood products.

Get A Quote

We will answer your email shortly!

Don’t want to be tied down? Click to send email directly crystal@lyzongnuo.com

Reviews

There are no reviews yet.