| Product Parameters | |||

|---|---|---|---|

| Size | 1220*2440mm(4′*8′),2100*2500mm(Thickness ≤9mm) or upon request | Thickness | 2-30mm (2.7mm,3mm,6mm, 9mm ,12mm ,15mm,18mm or upon request) |

| Thickness Tolerance | +/- 0.2mm-0.5mm | Face/Back | Plain or Melamine Paper/ HPL /PVC /Leather / etc ( one side or both side melamine faced ) |

| Base Board | Raw MDF , MHR MDF(Green), FR MDF (Red) , HDF (Black) | Surface Treatment | Matt, textured, glossy, embossed or magic |

| Colors | Solid color (such as grey, white, black, red, blue, orange, green, yellow, ect.) ;Wood grain (such as beech, cherry, walnut,teak, oak, maple, sapele, wenge, rosewood, ect.) Cloth grain & marble grain. More than 1000 kinds color are available. | Certification | ISO ,CE,CARB ,FSC |

| Density | 650-1200 kg/m3 | Glue | E0/E1/E2 |

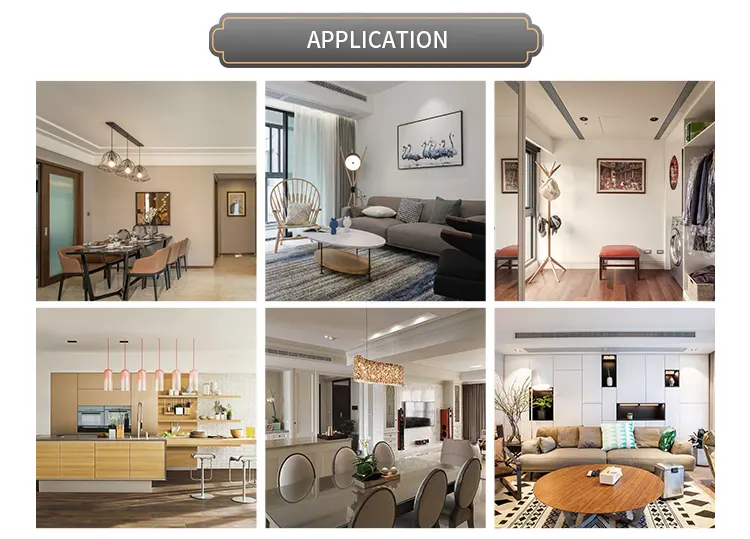

| Application | Furniture, interior decoration and wood flooring. | ||

| Standard Packing | Loose packing or Standard export pallet packing | ||

Further processing possibilities:

MDF can carry out various value-added processes, such as:

- Wood Veneer: Apply a thin layer of wood veneer to the surface to enhance visual appeal and simulate the appearance of real wood.

- Melamine Stickers: Add melamine film to provide different textures, patterns and colors.

- PVC: Use PVC to create a smooth, wear-resistant surface and edge banding.

Ordinary Core,Black Core,Fireproof Core,HMR Core

Widely used for construction materials and Day to day Works.

Core material

Finger Joint Blockboard

Glue: WBP Melamine

Thickness: 12/15/18mm

Reuse: 2-4 timesPrice: Cheap

Finger joint core is composed of smaller pieces of wood joined together with finger-like interlocking joints.

It offers excellent strength, stability, and resistance to warping or splitting.

Finger joint core is often used in high-quality plywood for applications that require superior structural integrity, such as construction, flooring, and furniture manufacturing.

Poplar

Glue: WBP Melamine

Thickness: 8/10/12/15/18mm

Reuse: 6-10 times

Price: Medium

Poplar core is made from the lightweight and straight-grained poplar wood.

It is known for its stability, ease of use, and affordability.

Poplar core plywood is commonly used in interior applications like cabinetry, paneling, and decorative projects where weight and cost are important factors.

Poplar

Glue: WBP Melamine/Phenolic

Thickness: 12/15/18mm

Reuse: 10 - 15 times

Price: Premium

Eucalyptus core is derived from the fast - growing eucalyptus tree, known for its strength and durability.

It provides excellent stability, resistance to moisture, and high load - bearing capacity.

Eucalyptus core plywood is often used in outdoor and marine applications, including boat building, exterior construction, and infrastructure projects.

MDF Application

MDF can be used in various industries, including:

- Furniture Manufacturing: It is widely used in the production of cabinets, shelves, tables and other furniture pieces, thanks to the stability, workability and smooth surface of MDF.

- Interior Design: MDF can also be used for wall panels, moldings, doors and floors, offering design and finish versatility.

- Construction: It can be found in houses with interior partitions, acoustic panels, false ceilings and architectural millwork.

- Wooden case packaging: MDF is used in packaging solutions including crates, pallets and display racks due to its strength and ability to be customized.

- DIY: Do-it-yourselfers will use it to give full play to their creativity.

Film Types

Anti-slip film

The special anti-slip film is usually used in the workshop to prevent the traffic of vehicles.

zzplywood® Plywood Veneer Film >>

Ordinary MDF

Widely used engineered wood product. It is made by compressing wood fibers and resin under heat and pressure, resulting in a smooth, uniform - textured board. This material is popular for furniture making, interior decoration like wall paneling and cabinetry.

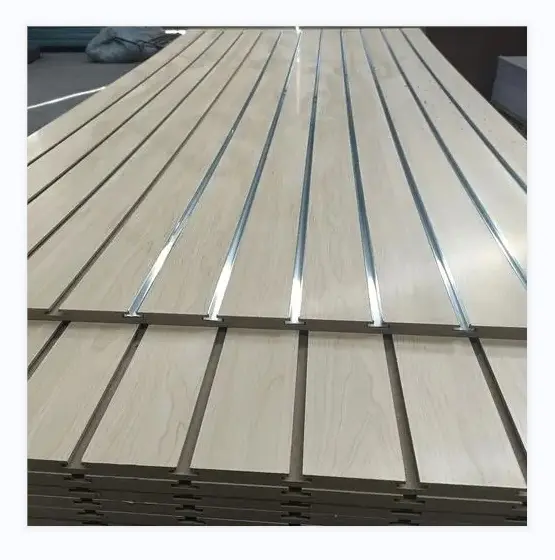

Slotted Wall Panel

Specialized architectural components designed to enhance both the functionality and aesthetics of interior spaces. Constructed from materials like high-quality wood, metal, or plastic, these panels feature evenly spaced slots running vertically or horizontally.

Fireproof Mdf

An engineered wood product developed with enhanced safety features. It is crafted by infusing the wood fiber - resin mixture during production with fire - retardant chemicals. This treatment enables the board to resist the spread of flames and reduce smoke emission.

Black Mdf

Stands out for its distinct appearance and versatile applications. It is created by either manufacturing MDF with black - pigmented resins during the production process or applying a high - quality black finish to standard MDF boards.

Hmr Mr mdf

Short for High Moisture Resistance Moisture Retardant Medium - Density Fibreboard, is an engineered wood product designed to combat high - humidity environments. It's crafted by compressing wood fibers and resins under heat and pressure.

Edge Seal - Waterproof

Waterproof edge sealing is an essential step in plywood protection and longevity. It helps prevent moisture penetration and protects the edges from damage. Remember, proper edge sealing is crucial to maximize the performance and longevity of form plywood, particularly in applications where exposure to moisture is expected. By taking the necessary precautions and using high-quality sealants, you can ensure the long-term durability and water resistance of your plywood products.

Get A Quote

We will answer your email shortly!

Don’t want to be tied down? Click to send email directly crystal@lyzongnuo.com